Previously, the process of sorting and packaging products consisted of two stages. First, for each product line to be packaged, products had to be manually organized and placed into boxes for easier access at the next stage. After that, an operator would insert each product box into a blister molded by the machine. This type of manual labor makes operators prone to work related injuries by repetitive movement, as tens of thousands of products are blistered every day. The project’s objectives were to automatize the blistering process and to reduce the need for intensive manual labor when sorting and placing boxes in the blisters, while being able to match the speed of the blister molding machine.

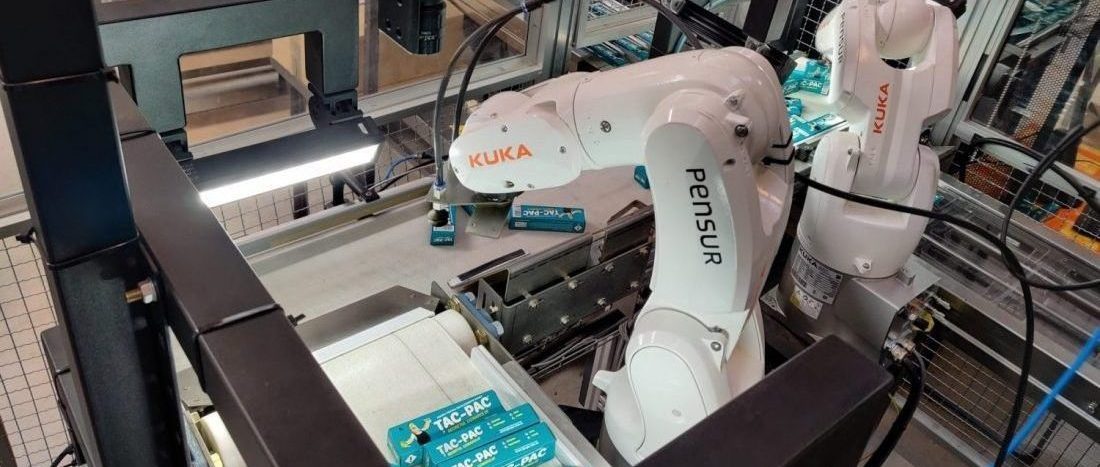

The solution developed by Pensur is a system that combines robotics and computer vision, in which two robotic arms are guided by industrial cameras using specifically developed software for this application.

The system receives the product boxes in an unordered manner. Then a conveyor moves them to the workspace of the first robot, where a camera identifies the orientation and position of each box and transfers this information to the robot which reorients them so they are ready to place into the blisters. Then, the correctly oriented product boxes are transfered to the second robot’s workspace, where another camera determines the position of each box, whether it is correctly orientated and if it is defective in some way. Correctly oriented products are then placed into blisters by the second robot matching the cadence of the molding machine. The whole process automatically adjusts to the speed of the molding machine and can reach up to 45 boxes per minute for the over 30 different products available.

Placing the boxes into blisters requires the pick and place error to be less than 0.5mm, so a custom calibration procedure between robots and cameras needed to be developed to achieve it. Additionally, custom easy-to-use product training tools were developed for the client to re-train the vision system when the product’s designs are changed.

The whole solution was developed entirely by Pensur using hardware from our strategic partners like Kuka, Lucid Vision, Siemens and Coval.

The pick and place system brings cost savings and increases employee’s productivity and safety on the production floor by maximizing labor efficiency and a high throughput. Also, the custom software also allows the client to automatically adjust and train the system to keep up with the ever changing designs in products without continuous interventions and reducing downtime.