During the refinement and packaging process, Azucarlito’s sugar refinement plant works 24 hours a day, packaging and palletizing 7 different formats of sugar bags at a maximum cadence of 1500 bags per hour. Originally, this task required a high rotation of manpower due to the physical fatigue of carrying bags of up to 25 Kg.

Automating the palletizing process with robots was proposed to achieve consistent results and to elliminate the more physically demanding tasks that can cause long term health issues.

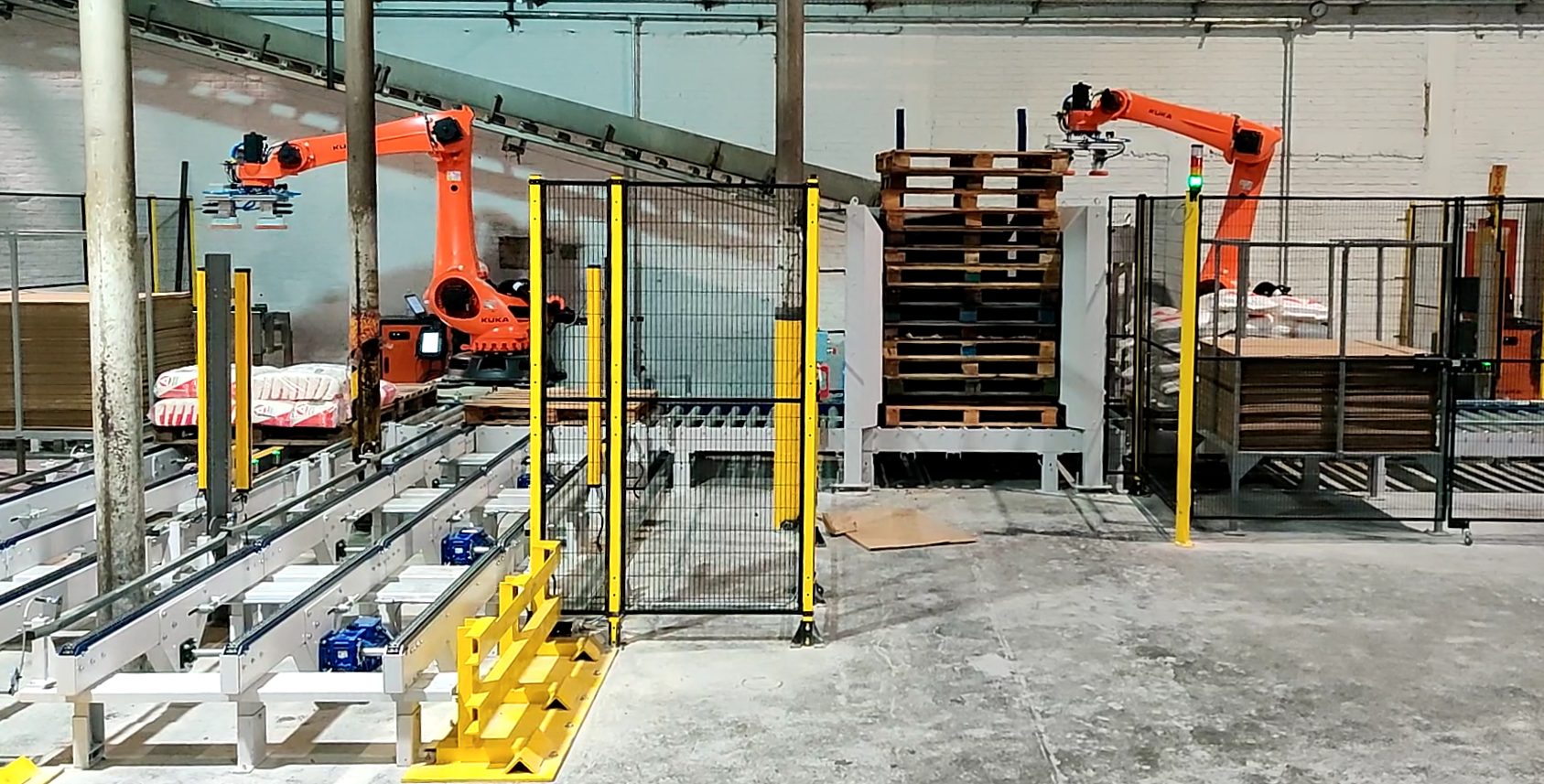

The solution designed by Pensur consists of 2 Kuka KR120 R3200 PA palletizing robots working in parallel, one dedicated entirely to 25 Kg bags for industrial use, working at a maximum rate of 700 bags per hour, and the other robot dedicated to the 6 formats of multibags (bags containing mulitple consumer sized bags), working at a maximum rate of 800 multibags per hour.

Both robots use grippers designed by Pensur that integrate vacuum technology from Coval to grab the bags using suction, which makes the process much faster, simpler and easier to maintain rather than a mechanical gripper. Both robots use this same gripper to also manipulate the interlayer cardboards, which they place in the corresponding layer according to the selected format. Additionally, the multibag palletizer robot can palletize two different pallets at the same time using different formats in different lines, for a total of three separate palletizing lines.

Aside from the robots, the palletizing cell has a pallet dispenser and a conveyor system that feeds empty pallets to all lines automatically, reducing to a minimum the exchange time between the exit of a finished pallet and the start of a new one.

The whole system works automatically and each line can be operated independently. Multiple control stations are placed around the cell for quick operator control and a screen can be used to make configurations, view statistics and events.

Due to the high speed, reach and force of the robots, security is paramount. The cell has multiple doors with monitored safety interlocks, emergency stop buttons and safety light barriers with muting to enable the exit of finished pallets. All these sensors, together with a safety analysis and correct implementation of safety standards make the system exceptionally safe for operators.

During the whole design, installation and commisioning process, we worked closely with the client to adapt every aspect of the project to their needs and workflow.

A robust and efficient implementation of the multi-format sugar bag palletizer system was achieved, maximizing the use of the available space. Thanks to the utilization of industrial robots and first grade components and materials, the system works without interruptions or major interventions. The implementation of the palletizing system allowed the improvement of the consistency of the palletizing, as well as the safety of the operators, with the flexibilty of being able to make format modifications in the future with only software changes.